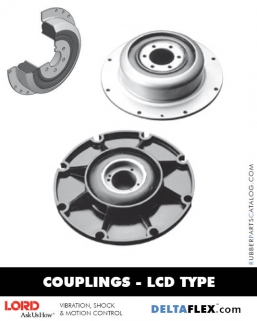

LORD DRIVELINE COUPLINGS - LCD SERIES

Horsepower Rated: 75 hp to 2000 hp at 2000 rpm

"Protect against torsional vibration, shock and misalignment..."

LORD LCD Series Couplings were developed to overcome numerous torsional problems associated with vehicular and industrial driveline systems. These couplings increase equipment life by protecting against torsional vibration, shock and misalignment.

Features & Benefits

- Torsional vibration isolation

- Protection from torsional shock loads

- Misalignment capacity

- Design flexibility

- Long service life

- Motion accommodation without wear or lubrication

- Noise attenuation

- Fits most standard SAE flywheels

- Safe for occasional severe overloads

Application Means of Attachment

- Flywheel to shaft

- Flywheel to hub (splined)

- Shaft to shaft

- Floating shaft

- & many more...

The Dynaflex coupling line has been developed to overcome numerous torsional problems associated with vehicular and industrial driveline systems. These couplings increase equipment life by protecting against torsional vibration, shock and misalignment. Other significant features and benefits are:

- Vibration Isolation: Extremely low torsional spring rate is achieved with the Dynaflex coupling, using elastomer in the shear. This allows for low system natural frequencies and isolation of first mode drivelne disturbances.</p>

- Damping at Resonance: the elastomer used in LCD couplings effectively reduce vibration at resonance.

- Shock Protection: Torsional shock loads are attenuated by large shear deflection of the elastomer. In the case of severe overloads, equipment damage is prevented by slippage between the elastomer and the outer housing.

- Misalignment Accommodations: Elastomer flexibility allowed for angular, parallel and axial misalignment.

- Long Service Life: LORD Dynaflex couplings have proven themselves under demanding rugged service conditions.

- Maintenance Free: Elastomer flexibility accommodates all motion without wear, eliminates the need for lubrication.

- Noise Reduction: No metal-to-metal contact elastomer attenuates structure-borne noise and isolates vibration from components that would act as noise generators.

- Attachment: Fits many standard SAE flywheels.

- Design Flexibility: Standard rubber molds are used to produce each different size coupling shown in this catalog. Often it is necessary to change metal components for custom applications. This is common.

- Systems Engineering: LORD has in-house computer capabilities for multi-mass torsional analysis to assist in proper coupling selection.

| LCD-0075-13R-A | LCD-0150-20R-C | LCD-0300-20R-C | LCD-1000-01-A † |

| LCD-0075-20R-A † | LCD-0150-25R-C | LCD-0300-25R-C | LCD-1000-01-C |

| LCD-0075-13R-C | LCD-0200-20R-A † | LCD-0400-01-A † | LCD-1500-01-A † |

| LCD-0075-20R-C | LCD-0200-25R-A † | LCD-0400-04-A † | LCD-1500-01-C |

| LCD-0075-41-C *5 | LCD-0200-20R-C | LCD-0400-01-C † | LCD-2000-01-A † |

| LCD-0075-44-C *5 | LCD-0200-25R-C | LCD-0400-04-C † | LCD-2000-01-C |

| LCD-0150-20R-A † | LCD-0300-20R-A † | LCD-0600-01-A † | LCD-0400-44-D |

| LCD-0150-25R-A † | LCD-0300-25R-A † | LCD-0600-01-C | LCD-0150-25-RC |

| *1 Prolonged exposure to temperatures in the 0°F range and below produces a significantly reduced slip torqure prior to driveline warm-up. This condition may result in the coupling's inability to transmit adequate drive torque for applications experiencing unusual cold temperature related parasitic loading. Please consult Lord Engineering for application review and approval. |

*2 Refer to SAE J620C for the flywheel numbers 6½, 10, 11½, 16; to SAE J927a for numbers 60, 80, 100, 120, 160. See tables 4 & 5. *3 See detailed drawings by part number for tolerances. *4 Pilot diameter tolerances are +.000 / -.005 for "A" and +.005 / -.000 in. for "C" diameters. |

*5 Blind assembly style with a notched periphery provides trouble-free, sliding assembly on flywheel drive pins when bolted access is not possible. Outer member is a composite material. *6 Use Woods Sure-Grip® Bushing type SK or equivalent *7 Tapered. |

Unless otherwise noted: .xxdim +/- 0.030 in. .xxxdim +/- .0015 in. It is advisable to refer to drawing of coupling before ordering since it is not practical to show all details in this data sheet. †Non-stock item |

| Part Type | hp Rating |

Attachment Variation |

Torsional Stiffness Variation |

| LCD | -0400 | -01 | -A |

|

Torque Requirements: Torque (lbs. - in.) = 63025_ rpm |

Standardization of Proven Concept

Using the experience gained in designing and producing special Dynaflex couplings, LORD has developed a new standard product line of heavy-duty Dynaflex couplings. These couplings have a specially designed elastomeric element bonded to a metal inner member which is then preloaded and friction-fit into an outer member.

This unique concept provides low torsional spring rates which effectively isolate critical vibratory disturbances in driveline and accessory systems, thus prolonging equipment life. Misalignment and torsional shock loads are absorbed by shear deflection in the elastomeric element.

The ability of the coupling to slip at the outer member with short duration shock overloads protects the driveline and accessory components from premature failure. The Dynaflex coupling has been particularly successful for diesel driven applications.

Dynaflex couplings are available in 75 to 2000 hp ratings at nominal 2000 rpm. Each size is also available in two stiffness values. These are referred to as the A and C stiffness values. The C stiffness parts are normally stocked.

Load Deflection Data

Figures 1 through 3 illustrate the torque or load versus defection characteristics for the -A and -C stiff nesses of the LCD-0400 size couplings. The general characteristics of these curves are typical for all Dynaflex couplings.

Figure 1 shows the linearity of the coupling spring rates at (and well above) the rated capacity of 12,500 lbs-in. torque. The curves also demonstrate the unique overload slip characteristic at about 60,000 lbs-in. torque. It should be noted, however, that the overload protection results from slipping of the coupling. This slipping generates heat, and therefore continuous running at overload could be injurious to the coupling.

Figures 2 and 3 illustrate the flexibility of Dynaflex couplings to accommodate axial and radial misalignment. The "A" variation is made in a softer elastomer to produce a lower torsional spring rate and therefore had the lower axial and radial spring rates. All spring rates are ideally linear over the normal operating range of deflection.

Dynamic Torsional Stiffness, Kθ

The dynamic torsional stiffness is higher than the static stiffness at room temperature. When the LCD couplings are attached to diesel engine flywheels, the elastomer gets warm. At operating temperature in the 170° to 200°F range, the dynamic stiffness is nearly the same as stiffness at room temperature. The stiffness values shown in the performance characteristics chart are for computer modeling and in other types of torsional analysis work.

Static Load Deflection Characteristics of LCD-0400-01-A & -C and LCD-0400-04-A & -C

Curves of other LCD parts show similar characteristics and are available upon request.

Typical Applications

Dynaflex couplings are useful for a wide range of rotary rive applications, from off-highway truck drivelines to auxiliary compressor drives on diesel locomotives. The soft torsional stiffness of these couplings makes them ideally suited for diesel applications with remotely mounted driven components. Typical applications have included:

In addition, Dynaflex couplings have also been used in these types of applications:

Main Drive

Engine — Generator; Engine — Compressor;

Engine — Transmission; Engine — Pump;

Electric Motor — Pump; Electric Motor — Compressor

Accessories

Starters; Fans and Blowers; Alternators; Power Take-Offs

Specifications

Materials

The elastomer used in the LCD coupling is a high quality natural rubber which meets LORD specifications (available upon request) and exceeds SAE standards. Natural rubber is used because of its excellent physical resistance, fatigue resistance and low temperature characteristics. The elastomer-to-metal bonds are even stronger than the elastomers.

Standard LCD catalog parts are all made in two stiffnesses of natural rubber. The A elastomer is per LORD Spec MAP092, having durometer of about 45. The C elastomer is LORD Spec MAP094, having durometer of about 57. The metal parts for this series are of alloy steel or ductile iron.

Environmental

Extensive experience with similar parts indicates that heavy-duty Dynaflex couplings will perform satisfactorily when exposed to the normal fluid, temperature and other environmental conditions found in driveline systems. For operation in ambient temperatures exceeding 170°F (77°C), consult LORD Corporation. LCDs are often recommended for use in applications where the temperature is above 170°F. Temperatures above 200°F could present problems. Customers should know what the ambient operating temperature is and whether additional air circulation can be provided. Consultation with LORD Corporation engineers is necessary if the ambient temperature is above 170°F.

Selection Guide

This selection guide can be used to determine the size and series coupling to suit your general requirements. Final selection of the specific coupling to satisfy all of the application requirements generally necessitates a system engineering analysis. These computerizes analyses of torsional systems can be provided by LORD Corporation Industrial Products Application Engineering Department.

Application Note

Sustained operation at torsional resonance can produce vibratory torques which might cause damage to the coupling and other driveline components. Please consult LORD Engineering for application review and approval.